raw material of handmade carpet – silk

the raw material of handmade carpet – silk

silk history

Another raw material of handmade carpet is silk that is made from the natural fiber of proteins and produced by silkworm.

According to legends, about five thousand years ago, a Chinese prince named Hesse Ling Hey discovered the secret of silk, which later became the title of the goddess of silk. Soon, silk was used for sweatshirts and for archery. For several centuries, the secret of the use of silk was preserved by the Chinese, and they exported a vast amount of silk in the form of woven fibers.

Its high price has led many people to seek the discovery of the secret of silk, which, according to myths, in the sixth century AD, two Bazilite priests managed to cross the Chinese border and hide silk cocoons in their cuffs. Thus, silk production has come out of the monopoly of China, but it has been the best quality silk and the largest silk producer in China for centuries.

The process of silk production

To produce silk, silkworm or wormwood worm is used to place the cocoon in a cocoon-like protein before it can connect its saliva, which contains protein and a glue material, to three points, and dance like yourself The silk fiber is taken from it.

To grow silkworms, there is a need for a hot spot without any air flow. The silkworm eggs are laid out on a bed of berry leaves, and the larvae are born of these eggs, and they reach from 7 cm to 10 cm within a month. To get silk, silkworms should be Continuous feeding on small leaves and staying in the shoots of the berry tree, a plant that is essential for their life.

The good quality of the blackberry tree has a direct relationship with the quality of silk, which is produced after the first month by the silkworm

They provide comfort for branches, and silkworms begin to tread a strand of fiber that is made up of protein and fiber gradually, after three or four days, completely wrapped in a silky layer and enters the stage of cement tilling at the moment of collection Avery cocoons collect the cocoons in their entirety, while others heat up too much to keep the cocoons up.

Qalyab cabling

To make the strands simple in the form of bullets, they use boiling water. The soft outer layer, which is a sticky substance, is cleaned and makes it easier to open the cake. This is called Qalyab cabling. Silk softened in the water on the rod It is assembled and instantly wrapped up to form fibers that contain several fibers. They are usually used to make up to seven to nine fibers from silk carpets.

The benefits of heating silk

In the process of heating after the extraction of water, the silk is exposed to the air, and this way the adhesion between the different fiber fibers increases. Extremely heat-free silk has a low adhesion and so much resistance. Because of this, rushing without heat is used to obtain lower quality silk and often uses spoiled cocoons during assembly.

Silk Characteristics

The essential feature of silk fibers, even with a very low diameter, is tensile strength, which makes the fibrous silk ideal for carpet with high-density knitting. Silk is a continuous longitudinal strand, with a soft substrate and attractive appearance with high elasticity. Because of this particular cluster and softness, they are often used for full warp or special designs rugs.

Natural silk includes the following categories:

Raw silk: Silk, taken directly from the cocoon, and no gumming or scouring operations have been performed on them. The color of this silk is cream or yellow.

Boiled silk: the silk which its gum is taken and the color is white

Silk Flower: A good quality yarn made of high-quality, single-handed silk, is durable and resistant, and accepts uniform colors.

Kejin silk: Silk made from silk scraps of the bottom of the fiber and the remaining cocoa, which is, in fact, the undamaged part of the fiber

Rayon or viscose

One kind of synthetic fiber that looks very similar to the natural silk fibers and because of this they called synthetic silk. because these fibers aren’t durable, soft, and don’t have other necessary properties for use in handmade rugs they shouldn’t use in handmade carpet, but some benefactors use these fibers in handmade carpets in the name of the natural silk

Methods for identifying natural silk from synthetic silk

Burning method:

If we close the natural silk to the flame and move away from it, it will accumulate. It also burns slowly in the flame, and some of it melts and it smells burning feather. it produces blackish ash and is simply crushed and softened.

But Rayon burns off the smell of rubber when burned, and the gray is a hard and hard mass

Natural silk increases its strength by absorbing moisture, while Rayon loses its resistance by dampening and torn with a little force.

Chemical method

The natural silk in the diluted powder solution is completely dissolved, but the Rayon does not change. The concentrated hydrochloric acid and sulfuric acid dissolve the natural silk well, but they do not work on Rayon.

the usage of silk in handmade carpet

Silk rugs are made by very skilled weavers, and these weavers are able to use the best of silk. Extremely high expertise is required to work on silk fibers or texture with the precision of silk threads, and so the texture of silk carpets in geographically distinct areas. Today, the best silk sample takes place in some parts of Turkey and Iran, such as Any, Qom, Isfahan.

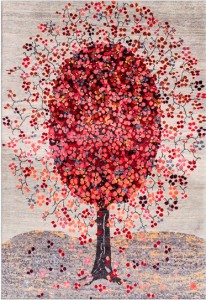

Farahan carpet is also used in some of its modern carpets with a special design a combination of natural silk with vegetable dyeing and hand spun wool that gives the polished and brilliant look to these carpets. Farahan carpet is always looking for the best quality of handmade carpets

Ordibehesht: modern rugs with a nice combination of natural silk and handspun wool

to see more rugs in the combination of silk and wool please go to this link

to see more picture of silk and wool rugs please go to this link

retrieved from Ghalin (author: Dr. Taher Sabahi)